Mechanical characterisation

Mechanical tests and instrumentation

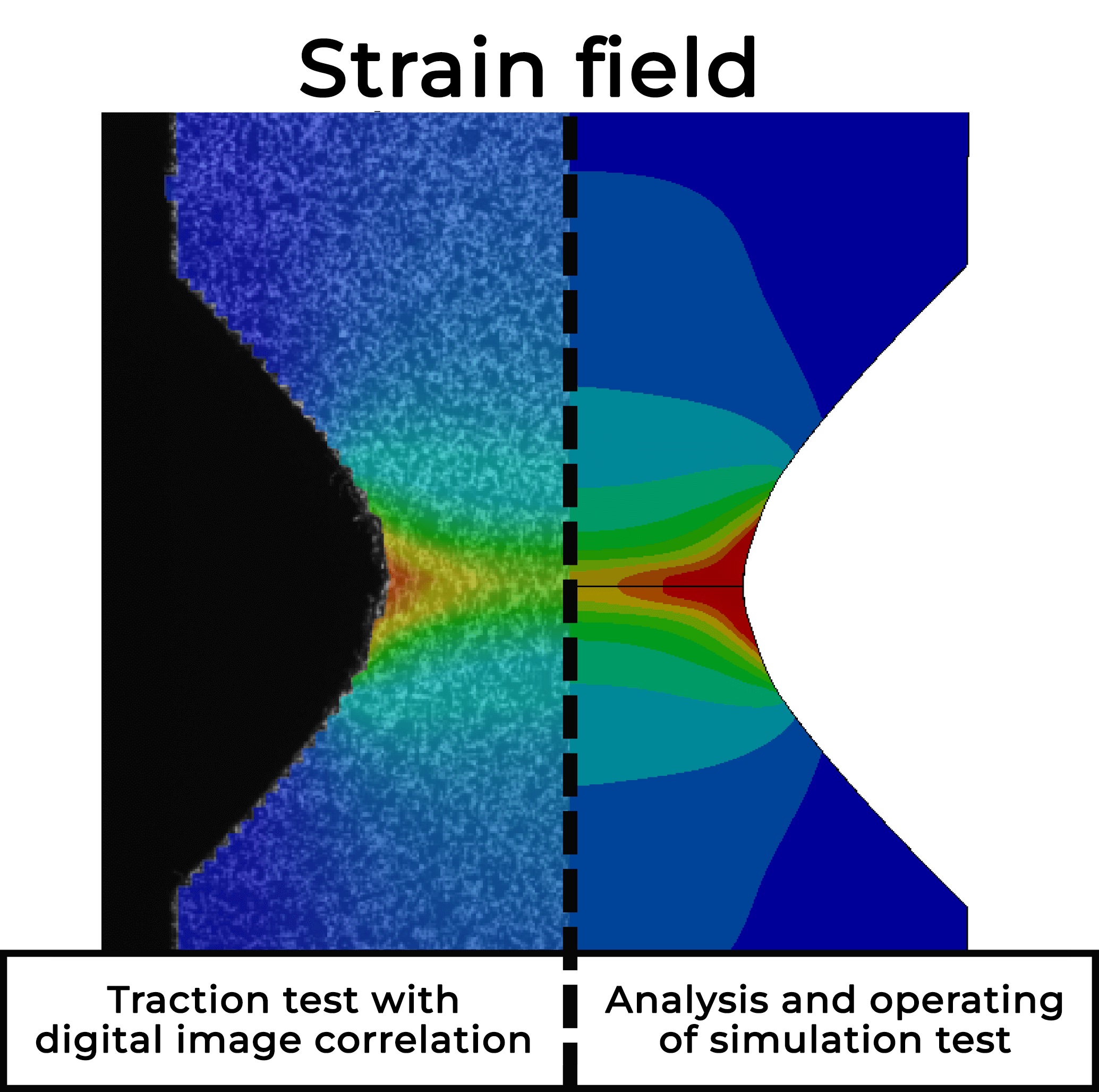

The static and dynamic mechanical characterisation tests for material and structures allow to measure physics characteristics such as Young's modulus and yield strength. The instrumentation of the experiments is performed with different tools such as :

Strain gauges, (very precise measurement of the deformation but on a very local area).

Digital image correlation, (which allows displacement or deformation fields to be measured over a large area using cameras).

The accelerometers...

Load cell.

Static testing machine

The machines and the results reached below are used for classic tests :

Tensile material testing system/ compression 10-50-250-500 kN

Tensile material testing system/ Compression and torsion 250kN et 2kNm

Stamped bucket

Conditioning of specimens in thermal and climatic chambers (-193°C + 200°C)

Thermomechanical test on Gleeble machine

Dynamics material testing systems

Instrumentalized catapult, maximum capacity 5 kg at 30m/s, with an impact volume of 800x800x250mm and temperature monitoring capability.

Drop tower with a drop height of 3m, for 500g acceleration tests during 4ms. A traction device has been developed to reach intermediates of 10 to 100/second.

Hopkinson bars (for fast traction and compression tests)