Material testing system: MATandSIM experimental devices

The different devices available

We design and sell our own material testing system in Lorient, Brittany

Our machines have a standardized base, nevertheless they are completely customizable according to your needs and are CE certified.

Their purpose is to test the strength of your materials or structures directly on site in your laboratory or in your company

Available upon request.

From 8 to 12 weeks for completion.

We deliver in France and abroad (Switzerland, Germany, Belgium...).

Designing and manufacturing material testing system

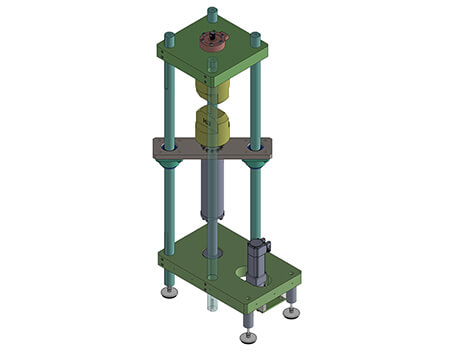

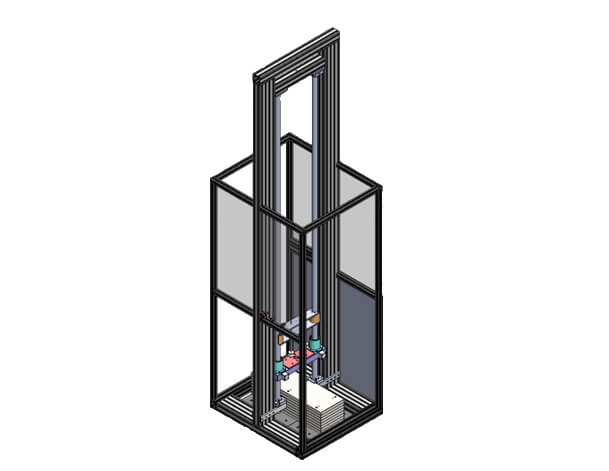

Conception and manufacturing of a tensile material testing system for automated tests.

Conception of a tensile test machine frame (with a capacity of 25kN) in order to carry out a very large number of mechanical characterisation tests thanks to the loading of the specimens made with a robotic arm and the entire data analysis process being automated.

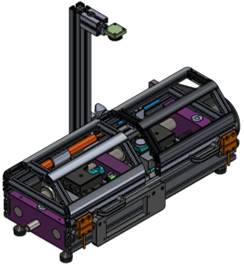

Material testing system of a support for ballistic tests on a helmet.

This material testing system is a support for testing the perforation resistance of a helmet in different orientations.

Manufacture of quasi-static test material testing system

Near-static tests are aimed to determine a behavioural law, but also to quantify the damage and failure parameters of the studied material.

All our machines are custom-made according to the type of stress that we wish to impose on the specimen.

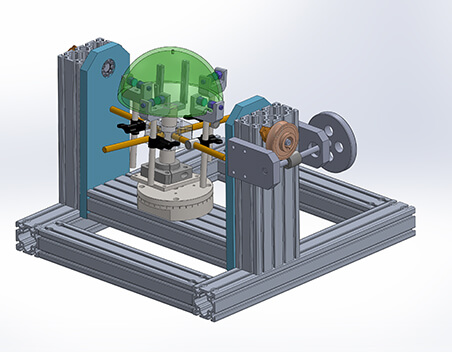

Symmetric tensile test machine

Symmetric tensile test machine with a 15kN capacity, which allows the centre of the specimen to be kept fixed relative to the frame, thus improving the accuracy of the digital image correlation.

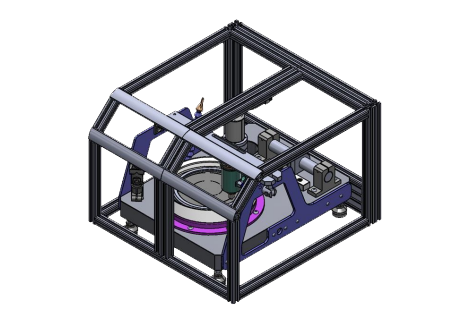

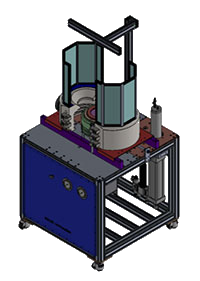

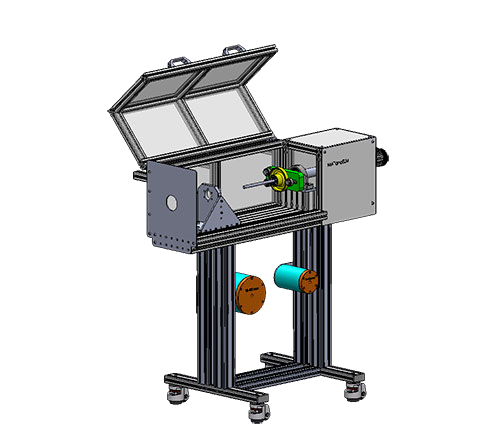

Automatic bulge test machine

Development of a material testing system to perform equi-biaxial expension tests or bulge tests on sheets metal samples according to the ISO16808 standard with a hydraulic specimen clamping system.

Analysis by digital images correlation of a traction test with the localisation of the deformations that spread along the specimen.

Quasi-static torsion material testing system

Shear test on a circular specimen, allowing to avoid the fracture initiation which is usually occurring on the edge of the specimen. This work is being carried out in cooperation with the Numerische Materialmodellierung team at ETH Zürich.

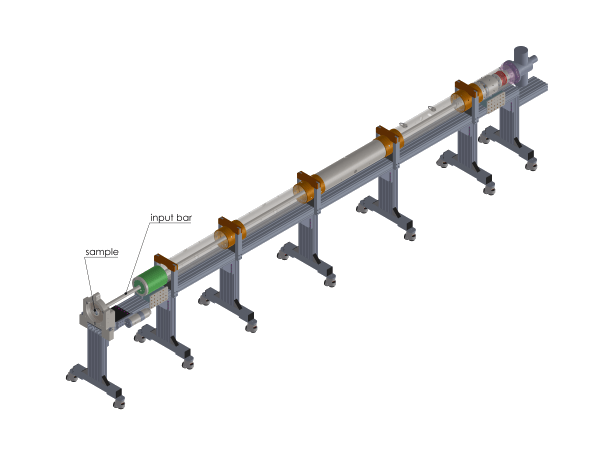

Manufacturing of dynamics testing material system

The purpose of this type of device is to quickly stress a specimen or structure, two types of machines are used.

- Principe of Hopkinson bars (usually used for testing small specimens but with strain speed rate up to 1000/s)

- Drop tower or catapult (which allows to test structures with slowerspeed)

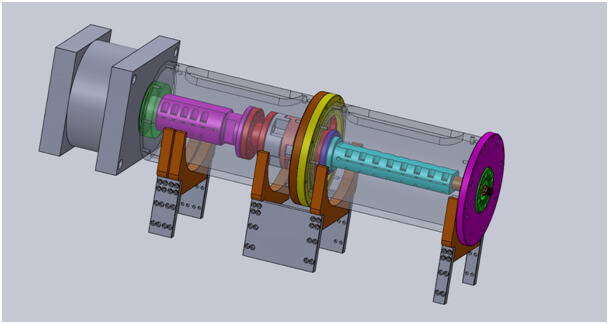

Dynamic torsion material testing system

We have fully designed a torsion material testing system using Hopkinson bars principle to perform shear tests on circular sheet metal specimens. This test also led to a patent on the torsion bar locking device.

Drop Tower

This bench is very easy to use because it allows tests to be carried out using the falling mass as a projectile or to accelerate structures (such as electronic boxes) when the carriage is stopped.

Fatigue material testing system

This material testing system allows to stress hydraulic couplings with a moment via a rotary bending and a pressure pulse inside the coupling. This material testing system is designed to respect the ISO 19879-2 standard, the frequency of the vibration is 10 Hz and the pressure pulse is 0.5 Hz.

The coupling is set valid when it is still operational after 10 million cycles of vibration.

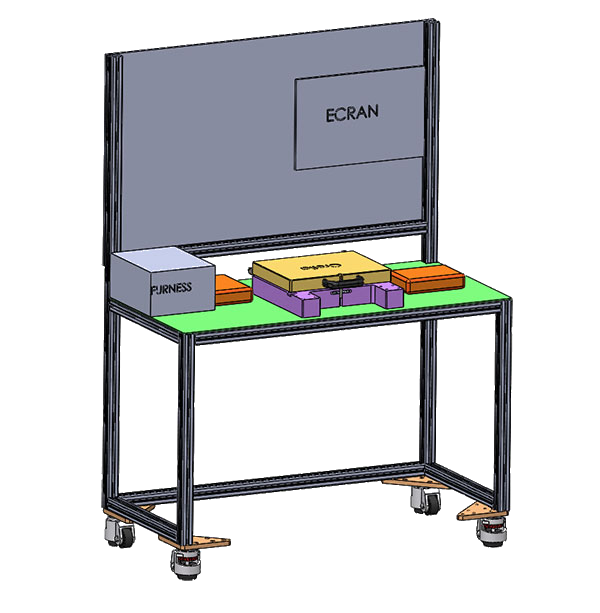

Sealing bench

The sealing bench is a test machine designed to test the airtightness of a box such as a black box. The bench is equipped with a pressure sensor that allows to perform leakage measurements. The silicone rubber gasket is custom made in order to guarantee the tightness of the block. This bench is easy to use, automated and adapted to the realization of series of tests thanks to its software coded in Python and open source.

Stick-slip system

This material testing system is a machine designed to carry out sound tests on rubber, with or without pressure loading, at regulated speed and with or without the presence of water.

During the test, the materials under test are subjected to compression at their edges on the moving part of the machine, which may or may not generate the stick-slip phenomenon. The sound generated is recorded by a microphone and then processed by a second piece of software.